- BY Diversion Strategies

- POSTED IN Uncategorized

- WITH 0 COMMENTS

- PERMALINK

- STANDARD POST TYPE

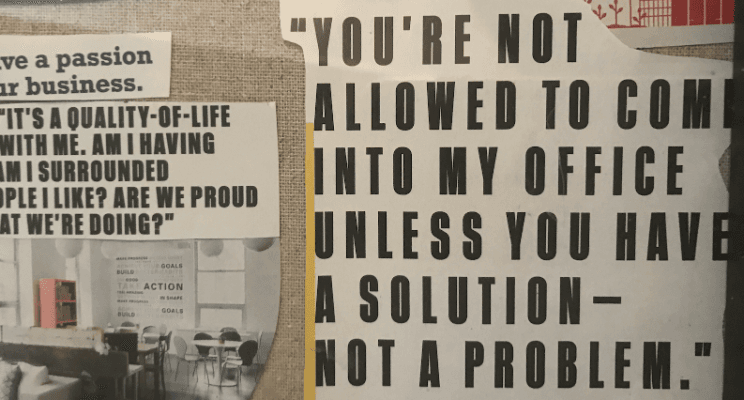

When my business partner Erin Merrill and I first dreamed of creating our own consulting firm, we created vision boards for Diversion Strategies and our non-profit, WISR that help guide us and keep us rooted in our values as we grow both organizations. I borrowed the quote pictured above from our Diversion Strategies vision board because it sets a standard for how we like to approach challenges, big or small. Start with solutions. Oftentimes there are many solutions to one problem. With that in mind, I decided to follow up on our previous blog post: The Cause of and Solution to Contamination in the Waste Stream by offering a proactive approach to tackling contamination from a manufacturer’s perspective.

Integrating a manufacturer’s mindset upstream isn’t easy. It involves many moving parts and requires varied approaches depending on the relationship between the manufacturer and supplier. Smooth execution of these principles is admittedly much easier in a vertically integrated system (where the supplier and manufacturer are owned by the same organization), but it is not impossible to do it as a stand-alone manufacturer.

For the purposes of this article, we will move just one rung up the supply chain to the material recovery facilities and transfer stations that generally accept this material from the collection routes in municipal operations. Due to strict regulatory requirements requiring putrescible solid waste to be moved quickly, this material must be managed efficiently with an attention to liquids management and vector control. More often than not, in the fast paced MRF and transfer environment, the push is to get it in and get it out as quickly as possible without much thought to the next link in the chain once it leaves the facility.

Oftentimes, in an effort to minimize liquids runoff, well-meaning equipment operators at transfer stations combine highly putrescible commercial food scraps with clean yard debris. Since pile management and truck logistics is a leading motivator for equipment operators, this combined feedstock will be quickly loaded onto a transfer truck and hauled to the organics management facility. The attention then gets turned to the next incoming load. The equipment operator, let’s call her Mary, has succeeded at pile management and flow control, but at what cost?

The cost, from both an economic and environmental perspective, multiplies exponentially under this scenario. In an era where contamination is becoming the norm instead of the exception at organics facilities, most manufacturers are forced to implement tiered pricing based on contamination levels of feedstock. The more contaminated, the more expensive it is to process. Why? Because contaminated feedstock carries expense through the entire chain of operations.

In the scenario above, unknowingly, Mary determines the cost of processing this feedstock. Let’s say Mary combined 10 tons of commercial food scraps with 10 tons of clean yard debris and let’s assume doing so resulted in 20 tons of combined feedstock with 5% contamination. If the organics manufacturer has tiered pricing based on contamination, the contaminated feedstock will pay a much higher gate rate resulting in increased costs to the supplier. Processing clean yard debris is straightforward and requires minimal labor and equipment costs because it goes directly from the hopper to the grinder with minimal if any sorting or screening needs. In the end, the supplier could have avoided paying the higher rate on 50% of the feedstock had Mary not combined the material in the first place. Mary’s solution for liquids management works, but it also costs.

First, contamination like film plastic leads to more equipment breakdowns, and a greater need for scheduled shutdowns to clean equipment of non-organics. This results in decreased equipment throughput and more costly labor hours for skilled mechanics. But these hard and easily quantified costs are nothing compared to the loss of employee morale and productivity when the flow of operations is disrupted due to equipment shut down. Even the best accountant in town can’t quantify these real costs.

Once the material is processed, contaminants result in less organic yield due to losing organics volume as “overs” since highly contaminated material must go through a trommel screen to separate organics from non-organic contaminants. These “overs” are typically disposed at a landfill. This is yet another reason manufacturers are implementing tiered pricing since both hauling and disposal costs are quantifiable and recoverable through rate increases. Oh, and what is that white stuff flying through the air? Even the most well-run organics management facilities deal with windblown litter due to plastics contamination if the operation is not housed completely indoors. A crew to pick up and manage litter on-site? Check and cha-ching.

Finally, increased contamination has lead to stricter standards on organics products. Whether it is an anaerobic digester trying to commoditize byproducts or a composter trying to get the best price for compost, contamination management is getting expensive. Not only are these manufacturers having to spend more on screening equipment, it is resulting in lower yields of product at a sometimes lesser value.

All of this begs the question whether reactive solutions like tiered pricing are truly the answer to the contamination problem. Or, is it merely a band-aid to cover the bleeding caused by increased costs due to an increasingly contaminated supply of material? Is there a proactive solution one rung up the supply chain that can be implemented to avoid the domino effect contamination has on the manufacturer?

Let’s imagine for a moment that earlier that day, Mary had attended her mandatory monthly safety meeting where a representative from the organics management facility was invited to give a presentation. In this presentation, Mary learned where the transfer trucks go after they are loaded, and what happens to the material once it arrives at the facility. She even learned that her neighborhood farmstand grows their produce using the manufacturer’s organic fertilizer. The operator explains why it is important to have specifications for incoming feedstock and Mary can see the impact of the plastics in the pictures the operator shares with the team at the transfer station.

During the presentation, discussion ensues about better ways to manage the feedstock and Mary offers the suggestion of building bunkers to house the commercial organics so liquids are contained without using yard debris. Mary also agrees to visually monitor the feedstock’s contamination level so it can either be sorted before delivery to the manufacturer or, if too contaminated, she can direct it to be disposed of at the landfill. All the while reducing costs to the transfer station and the manufacturer while enhancing employee engagement by empowering employees to create solutions.

Am I simplifying a complicated problem? Yes. But, it is to highlight the point that sometimes easy solutions like this one can make a huge dent in the problem. Solving the contamination problem requires real leadership, and any leader knows that the best solutions are found by bringing people together. In this case, the manufacturer and the operators at the transfer station. Ultimately, the operators will be the people to implement the solutions so they are the most well suited to help come up with them.

Imagine if this presentation was repeated monthly and implementing a manufacturer’s mindset became an expectation one rung up the supply chain? Imagine if the presentation was paired with a one-day job shadow so operators at the transfer station empathized with the manufacturer and vice versa? This is very doable in a vertically integrated system.

Interested in finding more proactive approaches to combating contamination in the waste stream and implementing a manufacturer’s mindset upstream? We’d be honored to hear from you. Contact info@diversionstrategies.com with inquiries.